My father, Edgar Villchur, obtained a patent on his invention, the acoustic suspension loudspeaker, in December 1954. When he was teaching at NYU after the war, one of his students was Henry Kloss, who had a business in Cambridge, Massachusetts, building wooden cabinets for loudspeakers. Villchur persuaded several friends to invest a few thousand dollars in his idea, and, in partnership with Kloss, started manufacturing speakers based on the newly patented principle.

They called the new company Acoustic Research, Inc.—AR. It was convenient to house the firm in Cambridge, where Kloss already had a going concern and business contacts. But it was also something Villchur wanted—distance from his residence, and a clear separation of his business life from his family life and the community of Woodstock.

Every Sunday afternoon, Edgar’s wife, Rosemary, and their daughter (yours truly) would drive north, from Woodstock to Albany, a trip of about an hour and a half. Edgar would board a plane to Boston. The flight between Boston and Albany took fifty-five minutes. So when we picked him up on Friday, we had to leave Woodstock before he even boarded his flight in Boston.

Albany airport is the oldest municipal airport in the US, with planes first landing there in 1908. It moved several times, had four major expansions—in 1962, 1968, 1979, and 1998—and is now the Albany International Airport, with service by major airlines and jumbo jets. In the mid 1950s, the terminal consisted of a small, square building with a ticket desk and a few vending machines.

Edgar Villchur was a reluctant businessman. His plan had been to sell the patent to a large manufacturer, but none of what he called “the big boys” were interested in it. He did have faith in his invention, and he knew that it was destined to be the future of loudspeakers. Henry Kloss agreed. They became partners, along with two business-oriented friends of Kloss’s. Their partnership lasted three years, at which point irreconcilable differences convinced Villchur to buy out Kloss and his friends, and to hire four of his own friends as executives. Kloss went on to found KLH speakers, which licensed the acoustic suspension design from AR and became a successful business. Although the old friends with whom Villchur chose to work did not have as much business experience, they all got along well, and they were all very smart. Two of the four had PhDs; three of them, like Villchur, were teachers; and one, Abe Hoffman, who became vice-president and treasurer, was a CPA.

As a young man, Villchur had been active in political causes, including the fight for workers’ rights. So when he had to opportunity to start a company, he decided to make it worker-friendly. The employee handbook, which he wrote, reads like a wish list for those who organized for fair employment practices.

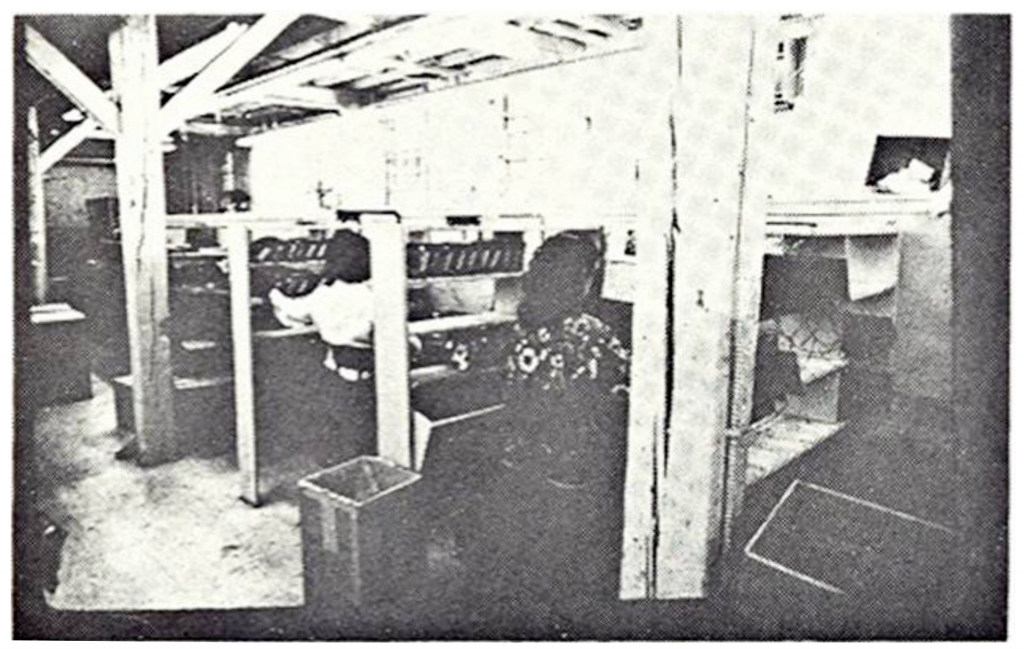

Perhaps the most innovative business practice Villchur instituted was a policy of complete nondiscrimination. In the employee handbook, this single paragraph, buried near the back of the book under the rubric “Employee Practices Required by Law” sums it up: “NONDISCRIMINATION IN HIRING AND PROMOTION,” and, under that, “AR policy (and Massachusetts law) does not allow job discrimination because of race, religion, sex, or age.” It may have been the law, but nondiscrimination was not the practice in Cambridge in the 1950s. When AR advertised the first job openings and began doing interviews, word quickly spread that this company was hiring on the basis of merit, not on the basis of race.

The result was that a great number of African-Americans applied for jobs at AR, and those doing the hiring were able to choose from a large population of highly intelligent and skilled workers whose abilities had been overlooked, ignored, or dismissed by other companies because of their race. Black employees were well represented among AR’s assembly-line workers, packers, office staff, and managers. Villchur used to talk about this with amazement: How could it be, he wondered, that he was the only one to figure out that hiring without racial prejudice resulted in hiring the best workers—what he called “the cream of the crop?”

He also made a point of paying more than the standard wage. A system was instituted for monitoring local wages, to ensure that AR always stayed roughly ten percent above what other companies in the area were paying.

Another major innovation that Villchur introduced was profit sharing, which he called a “wage dividend.” In those days, before Senator Bernie Sanders made it acceptable to label oneself a socialist, the idea of giving employees a stake in the company’s profits was unheard of, and executives of competing companies thought he was crazy. But if my father was going to be a corporate businessman, he intended to do it his way. In the employee handbook, written by Villchur himself, he explains the program:

“A portion of the company’s profit is distributed among AR employees twice a year. The ‘wage dividend’ is paid as a percentage of the employee’s earnings, including overtime, in the prior six-month period.

“Since each wage dividend depends on company profit, the amount, if any, cannot be predicted. AR’s history is that a wage dividend has been paid for every six-month period since 1957 [this edition of the handbook was written around 1963]; the lowest annual dividend amounted to an extra two weeks’ pay for the year, and the highest was equal to an extra five weeks’ pay, over and above vacation pay.

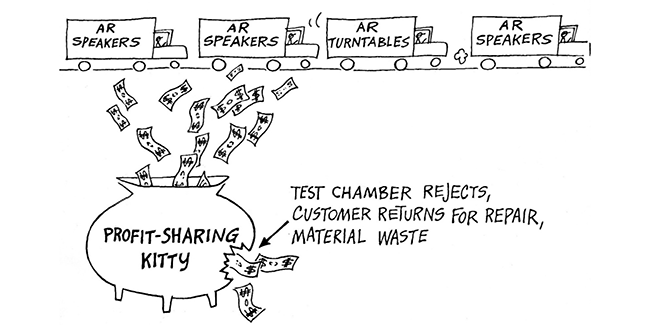

“For every AR speaker or turntable shipped, a certain amount of money may be thought of as going into the profit-sharing ‘kitty.’ In past years this amount has averaged about a dollar for each product shipped.

“For every AR speaker or turntable returned for repair under guarantee, much more than this amount is lost from the profit-sharing kitty, since the cost to AR of such a return is far higher than the original profit.”

It should be noted that AR’s return and repair policy was very generous. At the company’s beginning, each product sold came with a a one-year warranty; this was later changed to five years. Shipping, both to and from the factory, was paid by the company, and AR repaired its products no matter how they were damaged.

In an interview in Stereophile magazine in 2005, Villchur described several of the employee benefits at the AR factory. “And we had profit sharing,” he added, “which is meaningful only when wages are up to scale or better. We had twice-yearly meetings at which I’d announce what the profit sharing was. The highest figure was twenty-one percent of earnings for half a year. That was for the ordinary Joe; foremen and top management got more. While it’s what I believed in, it really is very good business, because the employees know that the better the quality of their work, the more their bonuses will be. We also made it clear to them that when something comes back because it fails, it takes far more out of the profit-sharing kitty than it ever contributed. Profit sharing stimulated efficient but careful work.”

Other employee benefits included major medical insurance for employees and discounted health insurance for their families; life insurance; disability insurance; sick pay; pregnancy separation pay (one week’s pay for each year of employment); two weeks’ vacation; pay for jury duty and military service; nine holidays each year; a twenty-five dollar savings bond (two hundred dollars in 2017 money) as a gift upon marriage or having a baby; three days paid leave for bereavement after the death of an immediate family member; and a discount of forty percent for employees buying AR products for their own use. These policies are generous even by today’s standards. In the mid 1950s, at a small manufacturing firm, they were unheard of.

The hi-fi business is seasonal, slowing down considerably during the summer. Villchur made it a priority to keep his workers employed year-round, so the summers were used as a time to build inventory for the busier winter months. During one particularly slow summer, some workers were given alternate jobs renovating the offices and painting the plant. The factory closed for two weeks in the summer, when employees were expected to take their paid vacation. Office workers continued to work during that time, and each office employee scheduled a vacation at the convenience of the worker and the company. Villchur was proud of the fact that AR had laid off only a few staff members, only one time, and that he was able to rehire those same employees later in the year.

In the mid-sixties, Harvard Business School published a three-volume, thousand-page textbook presenting several dozen case studies of actual businesses. Representatives of the school asked for, and received, permission to study the operation of AR, and researchers followed the workings of the company for six months. The summaries in the book ranged from twenty-five to over one hundred pages; Acoustic Research’s entry in the text occupied eighty-eight pages.

Villchur decided that Harvard would have full access to all company information, that the company would have no secrets, and that (unlike several other firms Harvard studied) no pseudonyms would be used. AR was named as the subject of the study, as were the actual executives.

At a meeting to introduce the Harvard study team, Villchur made an announcement to the assembled staff: “Before we get started here, let me introduce our guest. He’s from Harvard, and is not merely a student but is a research associate. And for some reason, he has taken an interest in us. Well, I just want to let you know that he represents Harvard and not us. Anything you want to say to him is all right with us. Go ahead. He’ll keep it to himself. If you want to call the president a “son of a B—,” that’s up to you, and it won’t come back to us [Much protest and laughter].”

The Harvard study of AR begins with a summary of what they call “The Phonograph Industry”—we would today call it “Stereo Systems” or “Home Entertainment.” In describing sound reproduction as high-fidelity—that is, the reproduced sound has a high degree of faithfulness or “fidelity” to the original music—they note that there are two main criteria: physical fidelity, which is measured by comparing the sound wave produced by the original with that of the reproduction, and physiological fidelity, which is measured by the more subjective criteria of what the listener perceives. Within physiological fidelity there are still objectively measurable tests: frequency response, or how wide a spectrum of frequencies is reproduced; flatness of response, or how even the volume of the recorded sound is at different frequencies; and freedom from distortion.

The introduction goes on to describe the divide between companies that made one-piece phonograph sets and those that manufactured components (mostly turntables, amplifiers, receivers, and loudspeakers). The former targeted the general public. The latter aimed their marketing at a group that soon became known as “audiophiles.” When stereo became widespread in the late 1950s, component sales increased, since the stereo effect (the quality that makes listeners feel as though an orchestra surrounds them) required a six- to ten-foot separation between the speakers, something that could not be achieved with an all-in-one console.

After describing the basic operations of AR, the Harvard study team concentrated on the policies that made AR different from other audio manufacturers. Villchur set the dealer discount at thirty-five percent, which was low for the industry. Unlike practically every other speaker manufacturer, AR did not solicit new dealers, did not offer quantity discounts, did not pay “push money” to get dealers to promote their products, and did not fix prices—dealers were allowed to sell at any price they wished. If they reduced the prices to the consumers, they would make less profit per unit but sell more units. Many dealers disliked these policies, but Villchur felt strongly that they were good for business because they were consumer-oriented. The Harvard investigators wrote, “AR’s marketing program was based on management’s belief that a superior product—once it became known—would sell on its own merits. Management believed that high quality at low prices would create its own market. Mr. A. J. Hoffman, vice president and treasurer, summarized the AR’s overall marketing approach as follows: ‘We depend upon the customer to beat the dealer’s door down and insist on AR. We just open the mail in the morning and count the orders.’”

Acoustic Research, Inc., thrived despite what industry leaders said were overly strict dealer policies and what most business pundits thought were unnecessarily generous job benefits.

Some other AR job benefits must be mentioned. AR gave everyone two ten-minute breaks a day, in addition to lunch. Coffee was available at no charge, and fresh-baked doughnuts were delivered from a local bakery for both breaks and lunch. Soup was available free at lunch. On payday, an extra ten minutes was provided before lunch so employees could cash their paychecks.

It should come as no surprise that the employees at AR were not only efficient and careful, but also extremely loyal to the company. Villchur often spoke of his workers with respect and affection. But he was never able to understand one particular quirk in the way employees felt about working at AR. The good wages, the excellent benefits, and the absolutely unique profit-sharing program—these were not the advantages AR’s employees valued the highest. Most of them, when asked about working at AR, said the same thing: what they liked best about working at AR was the free, fresh doughnuts delivered every day.

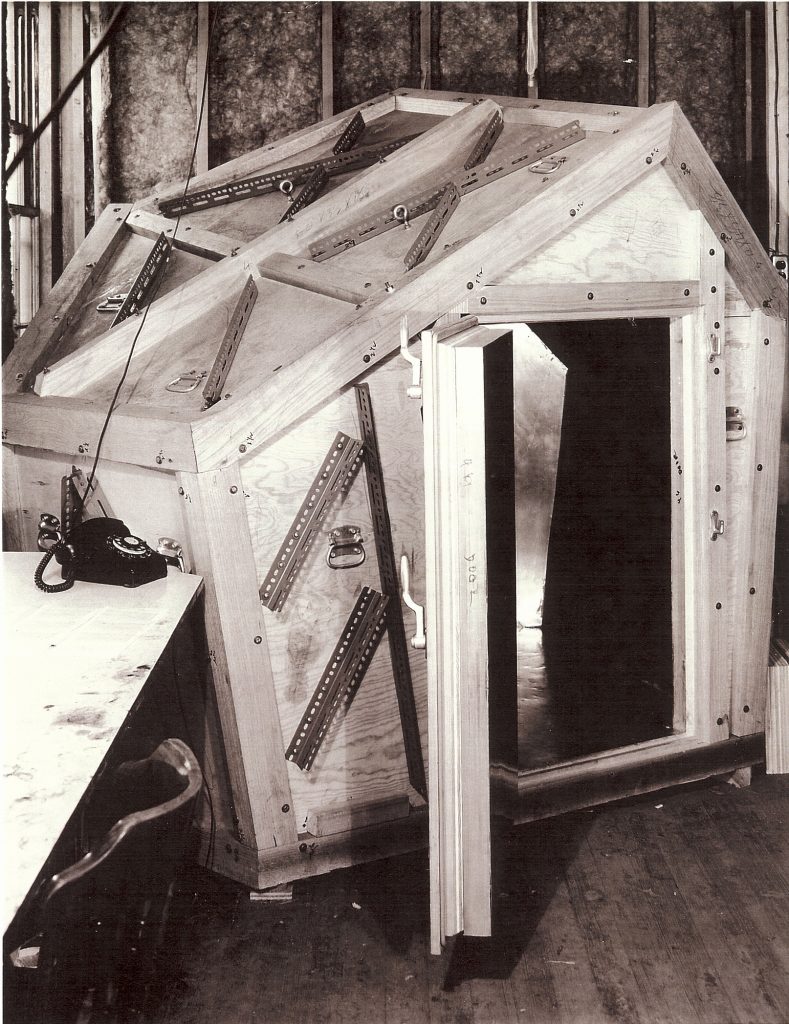

The illustrations used in this blog post are from the actual AR Inc. employee handbook, circa. 1963. To read the entire pamphlet, click here.

The Harvard study can be found on pages 431–519 of Business Policy: Text and Cases, by Edmund P. Learned, C. Roland Christensen, Kenneth R. Andrews, and William D. Guth. Published by Richard D. Irwin, Inc., 1965.

My sincere thanks to Tom Tyson for supplying many of the photographs used in this article.